Products & Solution

Tortilla Chips VFFS Packaging Machine

Category:

Snacks Food Packaging Machine

- Product Detail

- Application

- Technical Parameters

- FAQs

-

- Commodity name: Tortilla Chips VFFS Packaging Machine

LINYO's VFFS Packing Machine is a vertical form fill seal machine designed for high-speed and efficient packaging.It automatically forms bags from a roll of film, fills them with product, and seals them — all in one continuous process.

Tortilla Chips VFFS Packaging Machine:

LINYO's VFFS Packing Machine is a vertical form fill seal machine designed for high-speed and efficient packaging. It automatically forms bags from a roll of film, fills them with product, and seals them — all in one continuous process. This machine is ideal for packaging snacks, granules, powders, and other free-flowing materials. With stable performance and fast operation, it's widely used in food, pharmaceutical, and daily chemical industries.

Application for different attractive packaging forms:

The machine can process almost all mono and laminate packaging materials of different thicknesses to enable the production of a variety of bag styles. Depending on the packaging material the machines can also be equipped with diff erent sealing types like heat sealing, impulse welding for PE fi lms or ultrasonic sealing. Additional devices to produce bag styles like Stabilo Seal or doypack as well as printers, labelers and applicators for re-closing systems or zip-bags can be integrated in a space-saving way. The packaging task determines the machine equipment.Applicable Packing Materials:

Water-soluble film bag, PE film bag, composite film aluminized film, paper film, non-woven fabric, etc

Can Be Made in Bag Type:

Back sealed bag, Gusset stand up bag, 4 quadro seal stand up bag, flat four sided sealed bag, flat three sided sealed bag

Pillow bag Flat Bottom Gusset bag

Package Sample Dispay:

Vertical machine production line composition:

Z-type elevator Multihead weigher Supporting platform Vertical Packaging machine Finished product conveyor

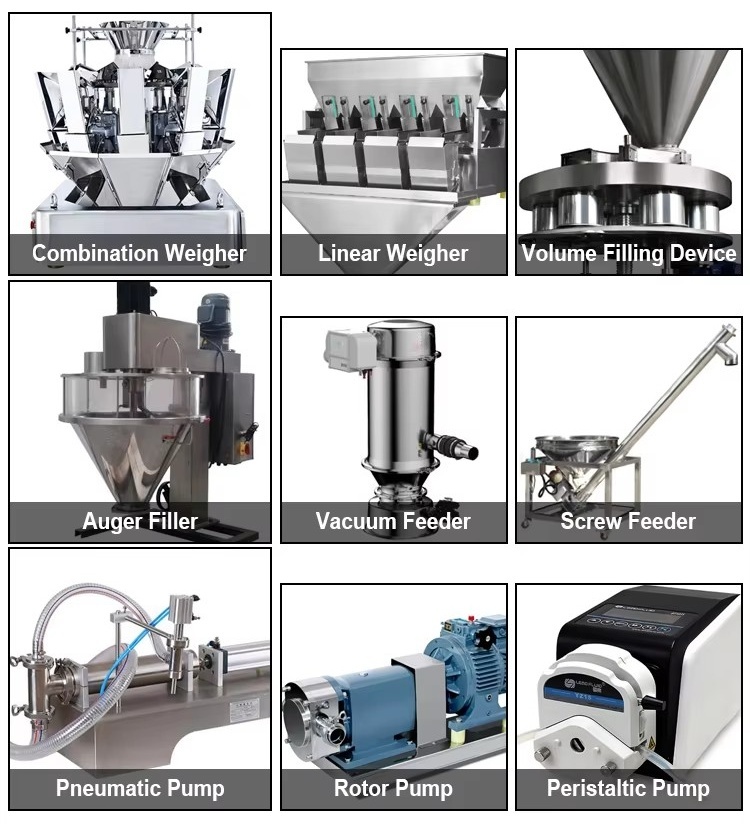

Measuring Filling Systems:

VFFS machines can be equipped with different types of filling systems, such as auger fillers, volumetric fillers, linear weigher, combination weighers and liquid measuring pump.

The choice of filling system depends on the product's characteristics, flow properties, and required fill accuracy.

-

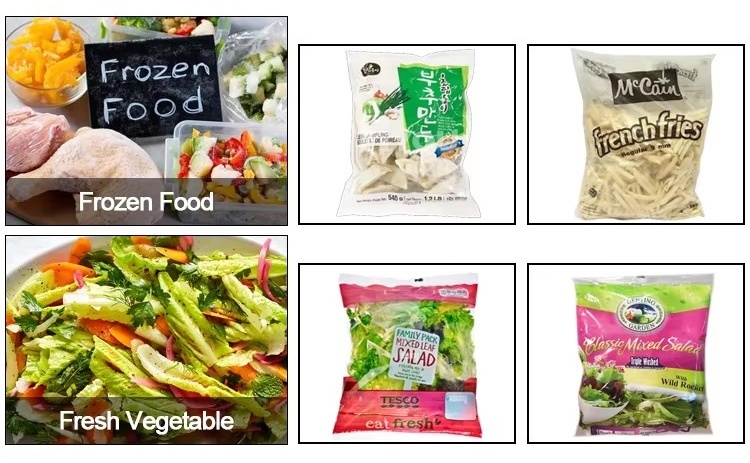

VFFS packing machines are widely used in various industries to package products such as food, pharmaceuticals, chemicals, cosmetics, hardware and fasteners, and medical supplies. These machines utilize a vertical forming tube to create a bag from a flat roll of film, which is then filled with the product and sealed.

Food Industry Applications

Snacks & Confectionery: Chips, popcorn, nuts, candy, chocolates

Dry Goods: Coffee, tea, rice, cereals, seeds, beans

Powders & Granules: Sugar, salt, flour, milk powder, spices, seasoning blends

Liquids & Semi-Solids: Ketchup, juice, milk, sauces, honey, syrups

Frozen Foods: Vegetables, meat, seafood, ready-to-eat meals

Non-Food Applications

Pharmaceuticals: Powders, tablets, capsules, herbal supplements

Chemicals & Detergents: Fertilizers, pesticides, cleaning agents

Pet Care: Dry/wet pet food, treats, cat litter

Cosmetics & Toiletries: Bath salts, face masks, shampoo sachets

Industrial & Retail: Hardware components, toys, small parts

-

High machine efficiency with perfect bag quality:

The continuous motion Form Fill and Seal machine VTC500H is designed for maximum output performance. The machine is equipped with the Sense&Seal product detection and the high-quality sealing technology Premium seal also at high speeds. This results in a very high machine efficiency whilst producing perfect bag quality. The product area is strictly separated from the drive area, which ensures that the machine satisfies even the most stringent hygiene demands. In addition, the machine can be quickly and easily cleaned.

Technical Parameters:

Model VTC500H Bag length 80-300mm Bag width 80-250mm Max roll film width 520mm Packing speed 180times/min Air consumption 0.5-0.7Mpa Power voltage Total power:11.4kw Technical characteristics:

1.Inteligent Anti-Empty Pouch/Anti-Material Pinching and Cutting Prevention Function2. Roll Fiim Tension Maintenance Control Function

3.High-Precision Color Mark Tracking, Encoder Automotic Bog Length Compensation Function

4.Fully Automatic Servo Correction System

5.Vacuum Film Pulling Slip Automatic Correction Function

6.High-Precision Six-Axis Full Servo Drive

Optional Features:

1. Date printer

2. Quad seal bag assembly

3. Bag-in-bag configuration

4. Flat bottom bag assembly

5. Hole punch (Euro slot or round)

6. Load shelf

7. Product settler

8. Gas flush

9. Static elimination

10. Tear notch

11. In-feed and take-away conveyors

12. Integration with variety of printers, metal detectors, label applicators, and checkweighers

-

Get a Quotation:

To ensure that we can provide you with accurate pricing and customized solutions, please click the button below and provide us with the following information:1. Bag sizes and shapes required.

2. Type of packaging material needed.

3. Product characteristics and flow properties.

4. Required fill accuracy. 5. Any special features required.

Thank you for your inquiry. We look forward to hearing from you.

Online consultation

Need help to find the right solution with our experts?

For inquiries about our products, please leave your E-mail and we will be in touch within 24 hours.

Copyright©Hebei LINYOPACK Intelligent Equipment Co., Ltd | Powered by 300.cn | TAG